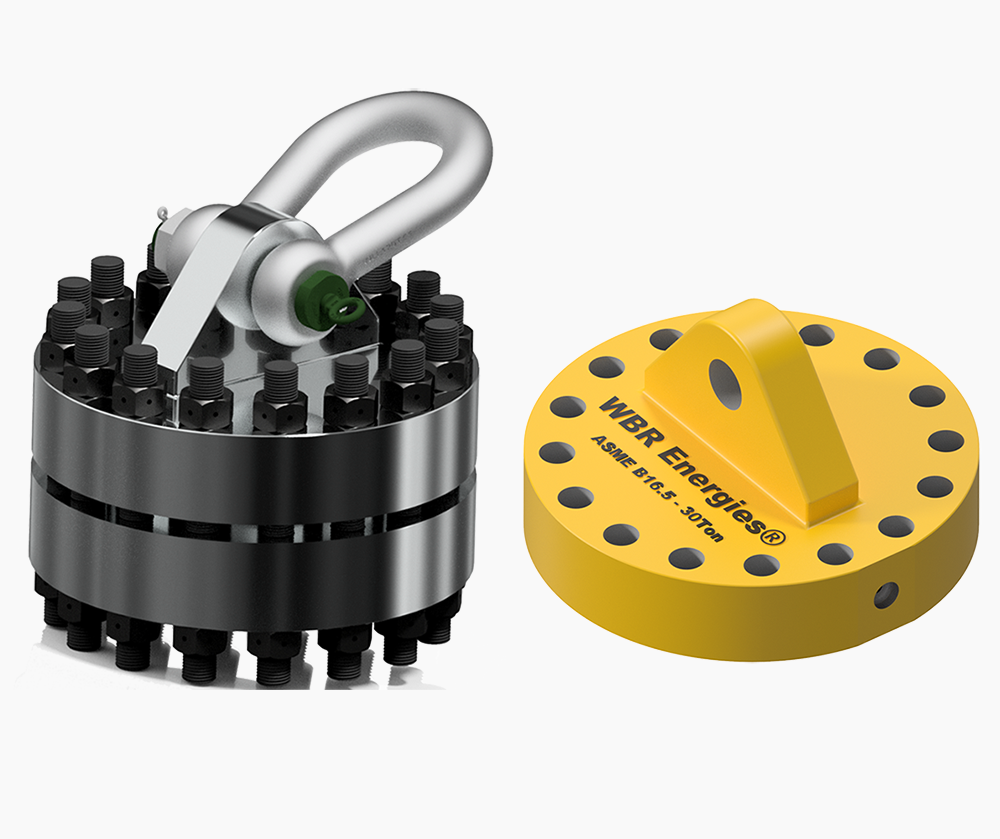

Pulling & Handling Heads

Pulling Heads and Handling Heads are designed and manufactured according to customer technical specifications. Design validation and manufacturing process are made following requirements of International codes (ASME, API & NORSOK).

TYPES

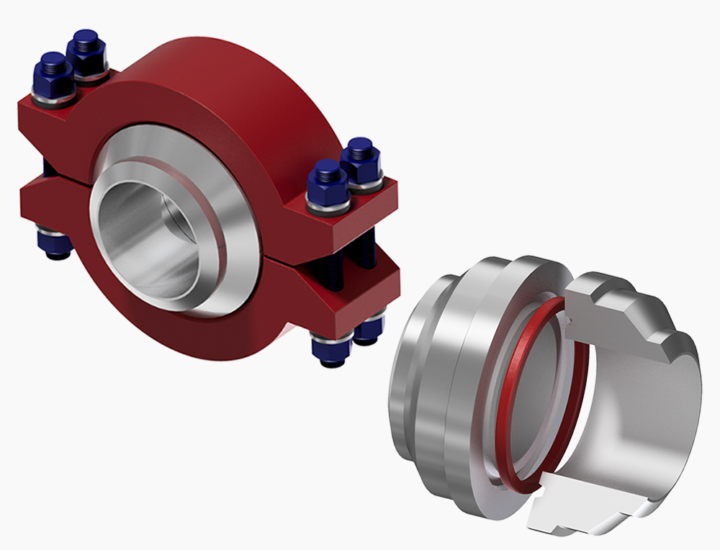

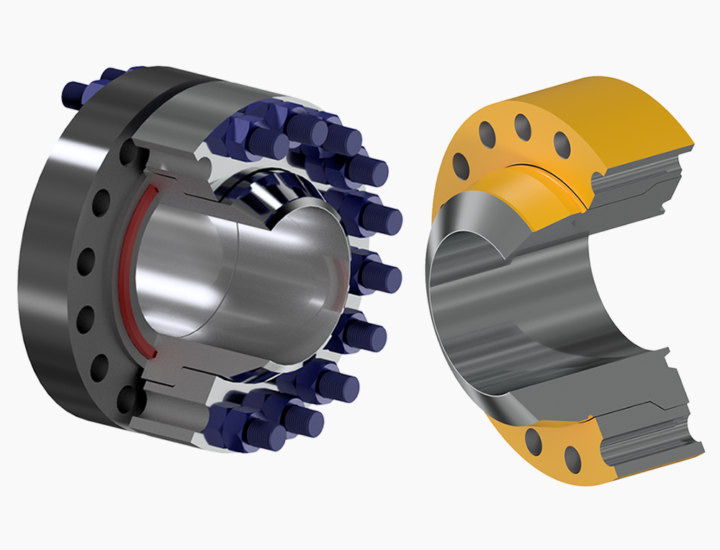

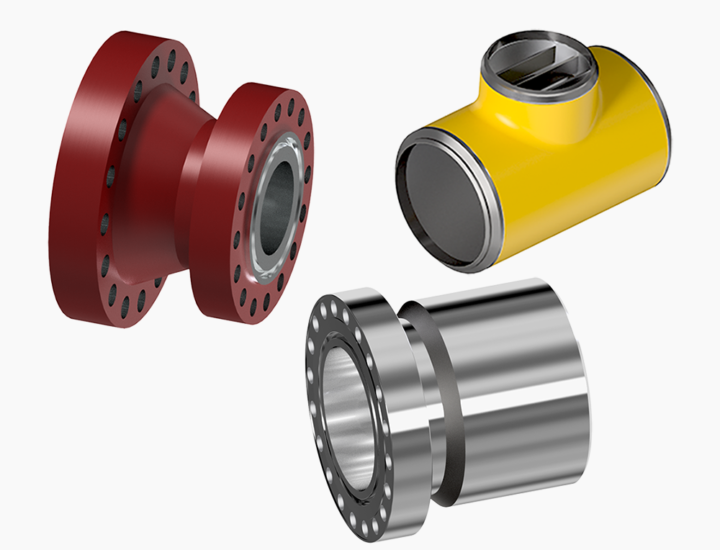

PULLING and HANDLING HEADS

ASME B16.5 / ASME B16.47 / API 6A / NORSOK L-005 / O-Ring Seal Solution

SIZES & RATING

ASME B16.5 / B16.47 : 4in to 60in – Class 150 to 2500

API 6A : 1 13/16in to 21 1/4in – 2000 PSI to 20000 PSI

NORSOK L-005 : 4in to 48in – Class 150 to 2500

ISO 3601 : O-Rings Seal Solution (maximal working pressure 100 bar)

DESIGN CODES

ASME VIII Div 2 : Rules for Construction of Pressure Vessels

API 16A : Specification for Subsea Wellhead and Tree Equipment

ASME B16.5 : Pipe Flanges and Flanged Fittings

ASME B16.47 : Large Diameter Steel Flanges

NORSOK L-005 : Compact Flanged Connections

ISO 3601 : Fluid Power Systems – O-Rings

MATERIALS

ASME A694: F42 / F52 / F60 / F65 / F70

ASTM A350: LF2 Classes 1 an 2 / LF1 to LF9

ASTM A150

API 6A : 36K / 45K / 60K / 75K

API A182 : F316 / 316L / F304 / 304L

API A182 : F51 / F53 / F55 / F22 / F5 / F9 / F11 / F91

SPECIALS: DUPLEX / INCONEL® / SUPER DUPLEX

**Other grades available under request

- Design ENGINEERING

- Project MANAGEMENT

- Custom MANUFACTURING

- Testing CERTIFICATION